Exam Details

Exam Code

:MB-320Exam Name

:Microsoft Dynamics 365 Supply Chain Management, ManufacturingCertification

:Microsoft CertificationsVendor

:MicrosoftTotal Questions

:230 Q&AsLast Updated

:Aug 27, 2023

Microsoft Microsoft Certifications MB-320 Questions & Answers

-

Question 131:

You need to configure lot number control for inventory.

Which option should you use?

A. Blank issue allowed

B. Primary stocking

C. Blank receipt allowed

D. Physical inventory

-

Question 132:

A manufacturing company uses master planning in Dynamics 365 Supply Chain Management.

The production planner increases the lead time of an item. On the next master planning output, the planner receives a cancel action message on existing purchase orders. The message includes a suggested earlier date for the planned purchase orders.

The demand for the item has not changed since the original purchase order was placed. Dynamic negative days is not used.

You need to resolve the issue.

What should you do?

A. Increase positive days.

B. Decrease negative days to be less than the item lead time.

C. Decrease positive days.

D. Increase negative days to be greater than the item lead time.

-

Question 133:

A manufacturing company uses master planning in Dynamics 365 Supply Chain Management.

Purchase orders for a raw material are created more frequently than needed. This results in missed discounts with the vendor who sells the raw material.

The raw material items have a 30-day lead time. The company is willing to delay sales and production order demand that may consume the raw material for up to 15 days to consolidate purchase orders.

You need to configure the setup to include lead time and consolidate purchase orders.

What should you configure?

A. positive days

B. dynamic negative days and negative days

C. negative days only

D. dynamic negative days only

-

Question 134:

You use the master planning module for Dynamics 365 Supply Chain Management.

Planned production orders have been created.

Several sales orders are canceled in response to concerns about recent online reviews of a product.

You need to enable the appropriate action message.

Which action message should you enable?

A. Increase

B. Decrease

C. Advance

D. Postpone

E. Derived actions

-

Question 135:

A company that makes artisan chocolate has implemented Dynamics 365 Supply Chain Management.

The top selling chocolate bar for the company must contain 85 percent cocoa. The cocoa can be obtained from either cocoa beans, cocoa butter or a combination of both, depending on supply at the time of production. The top three substitutions for the cocoa butter ingredient are configured in the system.

When you run master planning, all substitutions are out of stock at the manufacturing plant, but in stock at a secondary warehouse.

You need to process the planned orders.

Which type of planned order would be generated?

A. Sales order

B. Transfer order

C. Purchase order

D. Production order

-

Question 136:

A company uses Lean manufacturing processes with Kanban boards.

When unexpected transfer jobs occur, the board do not clear properly.

You need to ensure that the boards clear properly.

What are two possible ways to clear the board? Each correct answer presents a complete solution.

NOTE: Each correct selection is worth one point.

A. Change unplanned to planned.

B. Delete the unplanned job.

C. Revert the planned Kanban job status.

D. Remove the planned Kanban job.

-

Question 137:

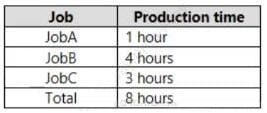

A company has three jobs in a job queue. JobB and JobC start while JobA is in progress. The following table shows the estimated production time for each job.

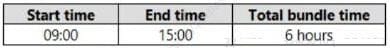

The actual work hours and total bundle time are shown in the following table.

You need to calculate the allocated time for JobA by using a job allocation key. What is the total allocated time for JobA?

A. 1 hour

B. 2 hours

C. 4 hours

D. 6 hours

E. 8 hours

-

Question 138:

A company uses production orders to assist with timely inventory delivery to the shop floor.

Inventory items for production orders are not being delivered from the warehouse in time for the production runs.

You need to ensure that the inventory items are available when needed.

Which option should you select?

A. Route card

B. Job scheduling

C. Job card

D. Batch job

-

Question 139:

A company configures master planning to order large and expensive aluminum sheets that are only available at certain times of the year.

The warehouse manager reports that replenishment levels are too high, causing inventory value to be over budget. In addition, the aluminum sheets take up too much space on the shop floor.

You need to configure the appropriate replenishment method.

Which coverage dimension should you use?

A. Min/Max

B. Per period

C. Per requirement

D. Manual

-

Question 140:

A pharmaceutical company is implementing Dynamics 365 Supply Chain Management.

The formulas for medication include a single active ingredient. The active ingredient will be defined with a target level and specified deviation ranges from the target.

You need to set up the active ingredient items.

Which two actions must you perform? Each answer presents a partial solution.

NOTE: Each correct selection is worth one point.

A. Configure inventory batch attributes.

B. Enable serial tracking.

C. Enable batch tracking.

D. Configure expiry dates for a batch.

Related Exams:

62-193

Technology Literacy for Educators70-243

Administering and Deploying System Center 2012 Configuration Manager70-355

Universal Windows Platform – App Data, Services, and Coding Patterns77-420

Excel 201377-427

Excel 2013 Expert Part One77-725

Word 2016 Core Document Creation, Collaboration and Communication77-726

Word 2016 Expert Creating Documents for Effective Communication77-727

Excel 2016 Core Data Analysis, Manipulation, and Presentation77-728

Excel 2016 Expert: Interpreting Data for Insights77-731

Outlook 2016 Core Communication, Collaboration and Email Skills

Tips on How to Prepare for the Exams

Nowadays, the certification exams become more and more important and required by more and more enterprises when applying for a job. But how to prepare for the exam effectively? How to prepare for the exam in a short time with less efforts? How to get a ideal result and how to find the most reliable resources? Here on Vcedump.com, you will find all the answers. Vcedump.com provide not only Microsoft exam questions, answers and explanations but also complete assistance on your exam preparation and certification application. If you are confused on your MB-320 exam preparations and Microsoft certification application, do not hesitate to visit our Vcedump.com to find your solutions here.