Exam Details

Exam Code

:MB-320Exam Name

:Microsoft Dynamics 365 Supply Chain Management, ManufacturingCertification

:Microsoft CertificationsVendor

:MicrosoftTotal Questions

:230 Q&AsLast Updated

:Aug 27, 2023

Microsoft Microsoft Certifications MB-320 Questions & Answers

-

Question 101:

SIMULATION

You are a functional consultant for Contoso Entertainment System USA (USMF).

The factory of USMF has a shift that runs during the hours of 06:00 to 14:00 from Monday to Friday.

You plan to create a calendar that will use the shift.

You need to create the factory shift in the system.

To complete this task, sign in to Dynamics 365 portal.

-

Question 102:

DRAG DROP

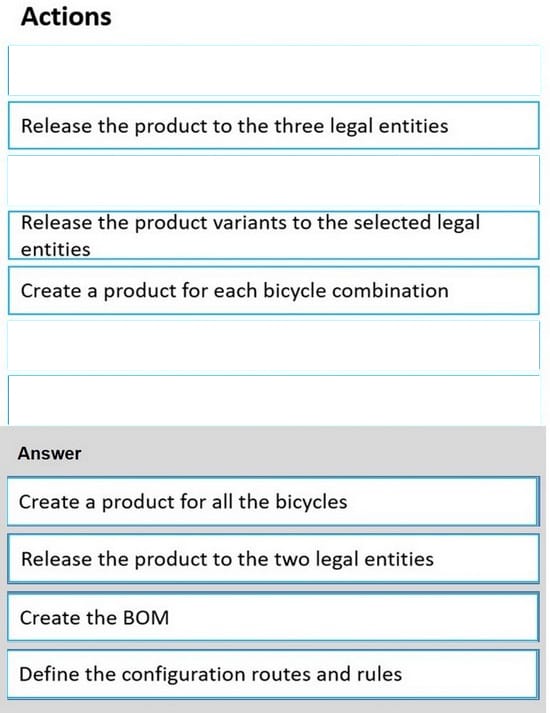

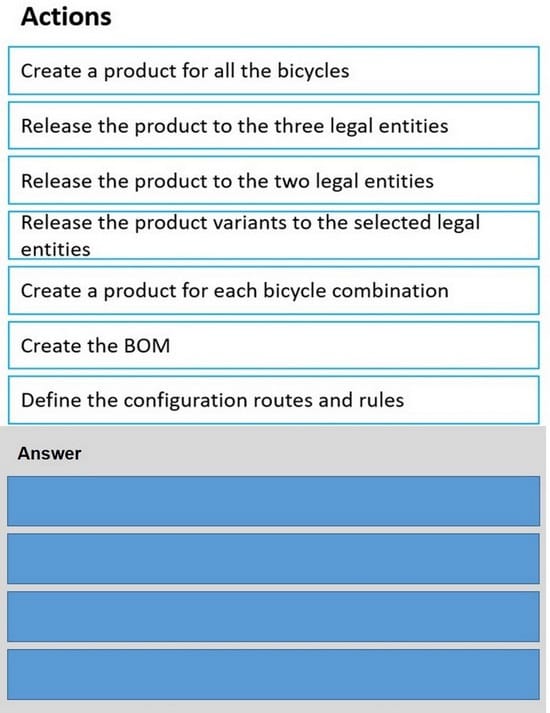

You need to create the new summer limited edition bicycle in Dynamics 365 in preparation for taking orders.

Which four actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

Select and Place:

-

Question 103:

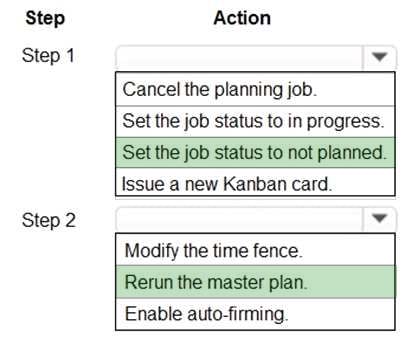

HOTSPOT

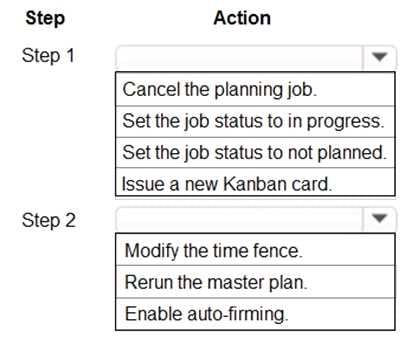

You need to resolve the shop supervisor's issue.

Which options should you use? To answer, select the appropriate option in the answer area.

NOTE: Each correct selection is worth one point.

Hot Area:

-

Question 104:

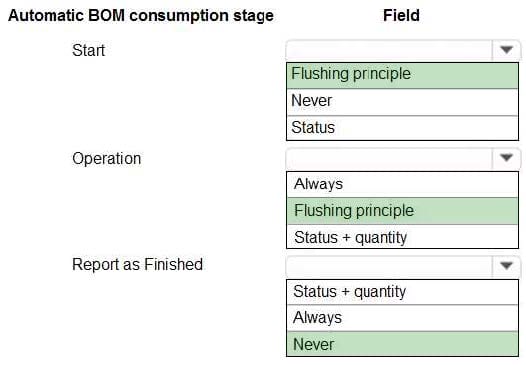

HOTSPOT

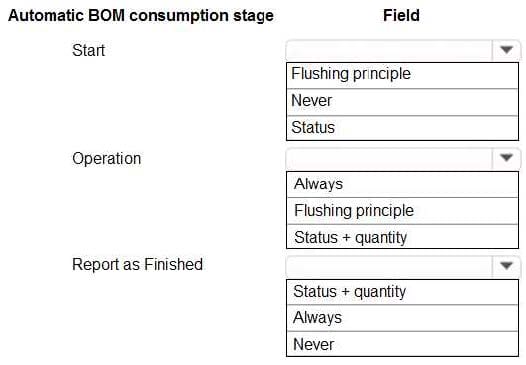

You need to resolve the production manager issue.

How should you configure manufacturing execution? To answer, select the appropriate option in the answer area.

NOTE: Each correct selection is worth one point.

Hot Area:

-

Question 105:

You need to set up the metal production route and BOM.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

Case Study Title (Case Study):General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

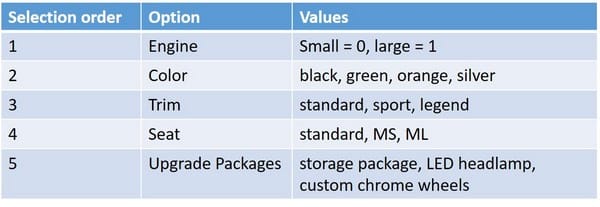

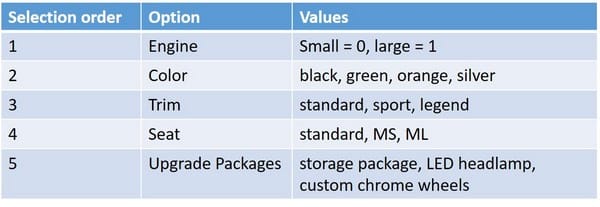

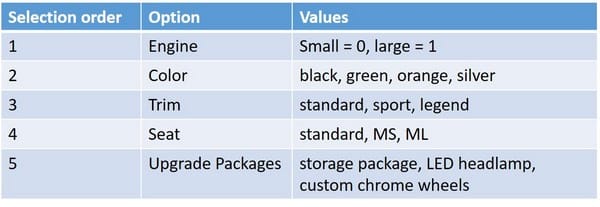

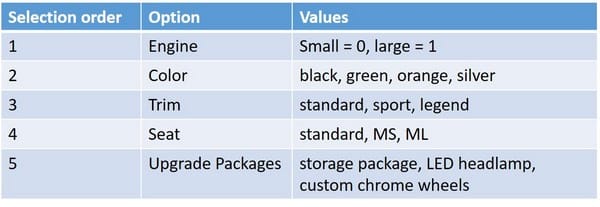

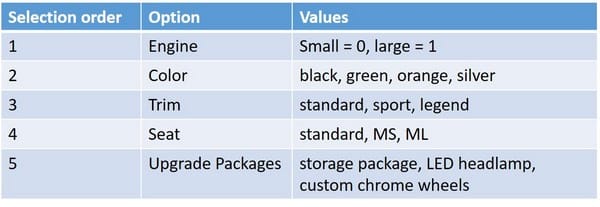

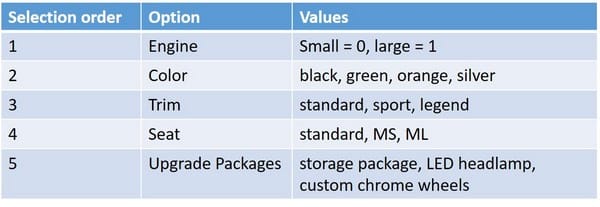

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

Customization restrictions

The following restrictions on customizations are in place:

*

Green color can only be sold with the Legend Trim.

*

Orange color can be sold with the Sport or Legend Trim.

*

The ML seat must be included in the Legend package.

*

The MS seat must be included in the Sport package.

Manufacturing facilities

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal Parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Sales Order

The company has the following requirements for sales orders:

*

During the configuration of a sales order, invalid combinations must be prevented.

*

Each configuration must create a unique bill of material (BOM) and Route based on options selected.

*

Sales pricing for the sales order must be based upon options selected.

*

Due to emissions regulations, the motorcycles cannot be sold to the state of California.

Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

*

Schedule labor only at the labor pool level without machines by day

*

Produce motorcycles within a scheduled day in any order.

*

Record actual production labor with start/stop times.

*

Record manager approval of labor entered prior to posting.

*

Post actual material consumption after production is finished.

Plastic manufacture

The company has the following requirements for motorcycle manufacturing:

*

Schedule both labor and machines.

*

Adjust schedules by using a Gantt chart.

*

Backflush standard labor by operation.

*

Post actual material consumption at the start of production.

*

Track and allocate costs to the excess plastic.

*

Report multiple molded part numbers during the same production run.

*

Determine the correct mold to use on a production order.

*

Generate a batch number for each production order.

Metal Parts

The company has the following requirements for metal parts manufacturing:

*

Schedule shipments to the vendor for painting.

*

Receive painted parts into inventory from the vendor.

*

Track vendor inventory levels.

Default You must configure defaults for manufacturing execution production orders to meet the followingrequirements:

*

Ensure accuracy for production order pick list posting.

*

Ensure correct pick list creation.

Issues

A. In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

B. The company is manually calculating an 8% overhead on materials and posting a journal manually.

A. Set the operation route type as Standard.

B. Set the input warehouse on the resource to the vendor warehouse.

C. Set the operation route type as Vendor.

D. Set all BOM lines warehouse to the production warehouse.

E. Set all the BOM lines to resource consumption.

-

Question 106:

You need to configure the system for plastic operations.

Which two parts should be manually reported as finished? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

Case Study Title (Case Study):General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

Customization restrictions

The following restrictions on customizations are in place:

*

Green color can only be sold with the Legend Trim.

*

Orange color can be sold with the Sport or Legend Trim.

*

The ML seat must be included in the Legend package.

*

The MS seat must be included in the Sport package.

Manufacturing facilities

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal Parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Sales Order

The company has the following requirements for sales orders:

*

During the configuration of a sales order, invalid combinations must be prevented.

*

Each configuration must create a unique bill of material (BOM) and Route based on options selected.

*

Sales pricing for the sales order must be based upon options selected.

*

Due to emissions regulations, the motorcycles cannot be sold to the state of California.

Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

*

Schedule labor only at the labor pool level without machines by day

*

Produce motorcycles within a scheduled day in any order.

*

Record actual production labor with start/stop times.

*

Record manager approval of labor entered prior to posting.

*

Post actual material consumption after production is finished.

Plastic manufacture

The company has the following requirements for motorcycle manufacturing:

*

Schedule both labor and machines.

*

Adjust schedules by using a Gantt chart.

*

Backflush standard labor by operation.

*

Post actual material consumption at the start of production.

*

Track and allocate costs to the excess plastic.

*

Report multiple molded part numbers during the same production run.

*

Determine the correct mold to use on a production order.

*

Generate a batch number for each production order.

Metal Parts

The company has the following requirements for metal parts manufacturing:

*

Schedule shipments to the vendor for painting.

*

Receive painted parts into inventory from the vendor.

*

Track vendor inventory levels.

Default You must configure defaults for manufacturing execution production orders to meet the followingrequirements:

*

Ensure accuracy for production order pick list posting.

*

Ensure correct pick list creation.

Issues

A. In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

B. The company is manually calculating an 8% overhead on materials and posting a journal manually.

A. unmachined plastic pieces

B. mold tooling

C. machined plastic pieces

D. excess plastic

-

Question 107:

You need to create the constraint for the ML seat selection.

Which expression constraint should you use?

Case Study Title (Case Study):General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

Customization restrictions

The following restrictions on customizations are in place:

*

Green color can only be sold with the Legend Trim.

*

Orange color can be sold with the Sport or Legend Trim.

*

The ML seat must be included in the Legend package.

*

The MS seat must be included in the Sport package.

Manufacturing facilities

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal Parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Sales Order

The company has the following requirements for sales orders:

*

During the configuration of a sales order, invalid combinations must be prevented.

*

Each configuration must create a unique bill of material (BOM) and Route based on options selected.

*

Sales pricing for the sales order must be based upon options selected.

*

Due to emissions regulations, the motorcycles cannot be sold to the state of California.

Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

*

Schedule labor only at the labor pool level without machines by day

*

Produce motorcycles within a scheduled day in any order.

*

Record actual production labor with start/stop times.

*

Record manager approval of labor entered prior to posting.

*

Post actual material consumption after production is finished.

Plastic manufacture

The company has the following requirements for motorcycle manufacturing:

*

Schedule both labor and machines.

*

Adjust schedules by using a Gantt chart.

*

Backflush standard labor by operation.

*

Post actual material consumption at the start of production.

*

Track and allocate costs to the excess plastic.

*

Report multiple molded part numbers during the same production run.

*

Determine the correct mold to use on a production order.

*

Generate a batch number for each production order.

Metal Parts

The company has the following requirements for metal parts manufacturing:

*

Schedule shipments to the vendor for painting.

*

Receive painted parts into inventory from the vendor.

*

Track vendor inventory levels.

Default You must configure defaults for manufacturing execution production orders to meet the followingrequirements:

*

Ensure accuracy for production order pick list posting.

*

Ensure correct pick list creation.

Issues

A. In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

B. The company is manually calculating an 8% overhead on materials and posting a journal manually.

A. Implies[Trim==Legend,Seat==ML]

B. Seat!=ML

C. [Trim==Legend|Seat==ML]

D. Implies[Seat==ML,Trim==Legend]

-

Question 108:

You need to set up the correct production solution for the assembly area.

Which solution should you implement?

Case Study Title (Case Study):General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

Customization restrictions

The following restrictions on customizations are in place:

*

Green color can only be sold with the Legend Trim.

*

Orange color can be sold with the Sport or Legend Trim.

*

The ML seat must be included in the Legend package.

*

The MS seat must be included in the Sport package.

Manufacturing facilities

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal Parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Sales Order

The company has the following requirements for sales orders:

*

During the configuration of a sales order, invalid combinations must be prevented.

*

Each configuration must create a unique bill of material (BOM) and Route based on options selected.

*

Sales pricing for the sales order must be based upon options selected.

*

Due to emissions regulations, the motorcycles cannot be sold to the state of California.

Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

*

Schedule labor only at the labor pool level without machines by day

*

Produce motorcycles within a scheduled day in any order.

*

Record actual production labor with start/stop times.

*

Record manager approval of labor entered prior to posting.

*

Post actual material consumption after production is finished.

Plastic manufacture

The company has the following requirements for motorcycle manufacturing:

*

Schedule both labor and machines.

*

Adjust schedules by using a Gantt chart.

*

Backflush standard labor by operation.

*

Post actual material consumption at the start of production.

*

Track and allocate costs to the excess plastic.

*

Report multiple molded part numbers during the same production run.

*

Determine the correct mold to use on a production order.

*

Generate a batch number for each production order.

Metal Parts

The company has the following requirements for metal parts manufacturing:

*

Schedule shipments to the vendor for painting.

*

Receive painted parts into inventory from the vendor.

*

Track vendor inventory levels.

Default You must configure defaults for manufacturing execution production orders to meet the followingrequirements:

*

Ensure accuracy for production order pick list posting.

*

Ensure correct pick list creation.

Issues

A. In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

B. The company is manually calculating an 8% overhead on materials and posting a journal manually.

A. Standard warehousing with Manufacturing execution

B. Standard warehousing for all transactions

C. Advanced warehousing for all transactions

D. Advanced warehousing with Manufacturing execution

-

Question 109:

You need to set up the configuration model to price the motorcycles correctly.

What should you do?

Case Study Title (Case Study):General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

Customization restrictions

The following restrictions on customizations are in place:

*

Green color can only be sold with the Legend Trim.

*

Orange color can be sold with the Sport or Legend Trim.

*

The ML seat must be included in the Legend package.

*

The MS seat must be included in the Sport package.

Manufacturing facilities

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal Parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Sales Order

The company has the following requirements for sales orders:

*

During the configuration of a sales order, invalid combinations must be prevented.

*

Each configuration must create a unique bill of material (BOM) and Route based on options selected.

*

Sales pricing for the sales order must be based upon options selected.

*

Due to emissions regulations, the motorcycles cannot be sold to the state of California.

Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

*

Schedule labor only at the labor pool level without machines by day

*

Produce motorcycles within a scheduled day in any order.

*

Record actual production labor with start/stop times.

*

Record manager approval of labor entered prior to posting.

*

Post actual material consumption after production is finished.

Plastic manufacture

The company has the following requirements for motorcycle manufacturing:

*

Schedule both labor and machines.

*

Adjust schedules by using a Gantt chart.

*

Backflush standard labor by operation.

*

Post actual material consumption at the start of production.

*

Track and allocate costs to the excess plastic.

*

Report multiple molded part numbers during the same production run.

*

Determine the correct mold to use on a production order.

*

Generate a batch number for each production order.

Metal Parts

The company has the following requirements for metal parts manufacturing:

*

Schedule shipments to the vendor for painting.

*

Receive painted parts into inventory from the vendor.

*

Track vendor inventory levels.

Default You must configure defaults for manufacturing execution production orders to meet the followingrequirements:

*

Ensure accuracy for production order pick list posting.

*

Ensure correct pick list creation.

Issues

A. In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

B. The company is manually calculating an 8% overhead on materials and posting a journal manually.

A. Set Order type in price model to Sales Order and Pricing method in Version to Attribute based

B. Set Order type in price model to Sales Order and Pricing method in Version to Cost based.

C. Set Order type in price model to Sales Quotation and Pricing method in Version to Attribute based.

D. Set Order type in price model to Sales Quotation and Pricing method in Version to Cost based

-

Question 110:

You need to set up the state control for sales of motorcycles.

Which two actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

Case Study Title (Case Study):General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

Customization restrictions

The following restrictions on customizations are in place:

*

Green color can only be sold with the Legend Trim.

*

Orange color can be sold with the Sport or Legend Trim.

*

The ML seat must be included in the Legend package.

*

The MS seat must be included in the Sport package.

Manufacturing facilities

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal Parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal

stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Sales Order

The company has the following requirements for sales orders:

*

During the configuration of a sales order, invalid combinations must be prevented.

*

Each configuration must create a unique bill of material (BOM) and Route based on options selected.

*

Sales pricing for the sales order must be based upon options selected.

*

Due to emissions regulations, the motorcycles cannot be sold to the state of California.

Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

*

Schedule labor only at the labor pool level without machines by day

*

Produce motorcycles within a scheduled day in any order.

*

Record actual production labor with start/stop times.

*

Record manager approval of labor entered prior to posting.

*

Post actual material consumption after production is finished.

Plastic manufacture

The company has the following requirements for motorcycle manufacturing:

*

Schedule both labor and machines.

*

Adjust schedules by using a Gantt chart.

*

Backflush standard labor by operation.

*

Post actual material consumption at the start of production.

*

Track and allocate costs to the excess plastic.

*

Report multiple molded part numbers during the same production run.

*

Determine the correct mold to use on a production order.

*

Generate a batch number for each production order.

Metal Parts

The company has the following requirements for metal parts manufacturing:

*

Schedule shipments to the vendor for painting.

*

Receive painted parts into inventory from the vendor.

*

Track vendor inventory levels.

Default You must configure defaults for manufacturing execution production orders to meet the followingrequirements:

*

Ensure accuracy for production order pick list posting.

*

Ensure correct pick list creation.

Issues

A. In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

B. The company is manually calculating an 8% overhead on materials and posting a journal manually.

A. Create an inclusive restricted product list for United States. Do not add the motorcycle part to the list.

B. Create an inclusive restricted product list for United States and add the motorcycle part to the list.

C. Create an exclusive restricted product list for California and add the motorcycle part to the list.

D. Create an exclusive restricted product list for Missouri and add the motorcycle part to the list.

Related Exams:

62-193

Technology Literacy for Educators70-243

Administering and Deploying System Center 2012 Configuration Manager70-355

Universal Windows Platform – App Data, Services, and Coding Patterns77-420

Excel 201377-427

Excel 2013 Expert Part One77-725

Word 2016 Core Document Creation, Collaboration and Communication77-726

Word 2016 Expert Creating Documents for Effective Communication77-727

Excel 2016 Core Data Analysis, Manipulation, and Presentation77-728

Excel 2016 Expert: Interpreting Data for Insights77-731

Outlook 2016 Core Communication, Collaboration and Email Skills

Tips on How to Prepare for the Exams

Nowadays, the certification exams become more and more important and required by more and more enterprises when applying for a job. But how to prepare for the exam effectively? How to prepare for the exam in a short time with less efforts? How to get a ideal result and how to find the most reliable resources? Here on Vcedump.com, you will find all the answers. Vcedump.com provide not only Microsoft exam questions, answers and explanations but also complete assistance on your exam preparation and certification application. If you are confused on your MB-320 exam preparations and Microsoft certification application, do not hesitate to visit our Vcedump.com to find your solutions here.