Exam Details

Exam Code

:CPIM-MPRExam Name

:CIPM - Master Planning of ResourcesCertification

:APICS CertificationsVendor

:APICSTotal Questions

:588 Q&AsLast Updated

:Jul 11, 2025

APICS APICS Certifications CPIM-MPR Questions & Answers

-

Question 311:

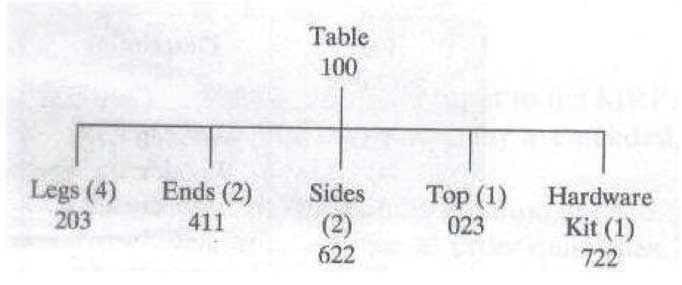

What the following figure shows:

A. The parent omponent relationship

B. Quantity and parts relationship

C. Identification of the parts

D. None of the above

-

Question 312:

Multilevel bills are formed as:

A. Logical grouping of parts into subassemblies based on the way the product is assembled.

B. Overall design for the arrangements of bills

C. To make identification of the part absolute

D. Both A and B

-

Question 313:

A convenient way to think about bills of material is through:

A. Product Tree

B. Dependent demand

C. Inventory record

D. All of the above

-

Question 314:

Which of the following points are related to bills of material?

A. The bill of material shows all the parts required to make one of the items

B. Each part or item has only one part number

C. A part is defined by its form, fit or function. if any of these changes , then it is not the same part and it must have a different part number

D. All of the above

-

Question 315:

The bill of material shows

A. The components that go into making the parent

B. The steps or process used to make the parent or the components

C. Both A and B

D. None of the above

-

Question 316:

Inventory records data are maintained in:

A. Inventory record file

B. Part master file

C. Item master file

D. All of the above

-

Question 317:

When a calculation is made to find out how many are needed, the quantities available must be considered in:

A. Maintaining the bills of material structures

B. Linkage between manufacturing planning and control system

C. Inventory records

D. Both A and C

-

Question 318:

Inventory Record is one of the major input to the

A. Capacity Requirements planning (CRP)

B. Material Requirements planning (MRP) System

C. Manufacturing Planning and Control (MPC) Function

D. Production activity Control

-

Question 319:

Master Production schedule:

A. A statement of which end items are to be produced, the quantity of each, and the dates they are to be completed

B. Drives the MRP system by providing the initial input for the items needed

C. Both A and B

D. None of the above is true

-

Question 320:

Master production schedule, inventory records and bills of material are three major inputs to

A. Material Requirements planning (MRP) System

B. Production activity Control

C. Manufacturing Planning and Control (MPC) Function

D. Capacity Requirements planning (CRP)

Related Exams:

CLTD

Certified in Logistics, Transportation and DistributionCPIM

Certified in Planning and Inventory Management (CPIM 8.0)CPIM-BSP

CPIM - Basics of Supply Chain ManagementCPIM-ECO

CPIM - Execution and Control of OperationsCPIM-MPR

CIPM - Master Planning of ResourcesCPIM-PART-2

CIPM - (Part 2)CSCP

Certified Supply Chain ProfessionalCTSC

Certified in Transformation for Supply Chain (CTSC)

Tips on How to Prepare for the Exams

Nowadays, the certification exams become more and more important and required by more and more enterprises when applying for a job. But how to prepare for the exam effectively? How to prepare for the exam in a short time with less efforts? How to get a ideal result and how to find the most reliable resources? Here on Vcedump.com, you will find all the answers. Vcedump.com provide not only APICS exam questions, answers and explanations but also complete assistance on your exam preparation and certification application. If you are confused on your CPIM-MPR exam preparations and APICS certification application, do not hesitate to visit our Vcedump.com to find your solutions here.